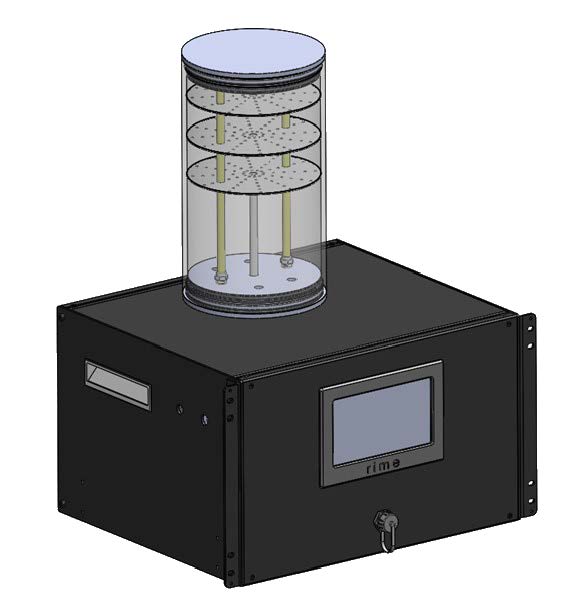

Slickfill is an automated oil fill station designed to provide a rapid, efficient and reliable oil filling solution for downhole drilling tools. Slickfill is designed specifically to eliminate the uncertainties associated with manual oil fill systems.

Slickfill incorporates an oil-less vacuum pump coupled to a seal free circulation pump. Slickfill also provides oil heating, deaeration and recirculation capabilities. all functions are automated using high vacuum solenoid valves, rugged relays, pressure and temperature sensors.

Slickfill is built around a touchscreen computer interface and has no mechanical valves, buttons, levers or gauges. All functions are controllable through the integrated software interface and the entire system is designed to operate in a stand alone mode allowing shop personnel the ability to focus on other tasks. Typical startup time is approximately 30 minutes (once a day to heat and deaerate the oil) and an oil fill can be performed in about 7 minutes.

Slickfill is capable of filling downhole tools in both single and dual port modes, and custom quick connects are available to adapt to various tool types in seconds. Slickfill also provides data tracking, automated logging and reporting capabilities.

| Specifications | |

|---|---|

| Dimensions | 17” wide x 15” deep x 23” tall (432mm x 380 mm x 583 mm) |

| Power Requirements | 110-120VAC 60Hz |

| Oil Volume | ~0.75 gal (2.84litres) operational volume |

| Oil Viscosity | 32 centistoke to 320 centistoke (ISO 32 to 320) |

| Heater | 125W |

| Oil Temperature | 30°C to 50°C (86° to 122°F) |

| Vacuum Capability | >29” HG |

| Max Pump Pressure | 35 psi |